Services

HANSUNG INDUSTRY

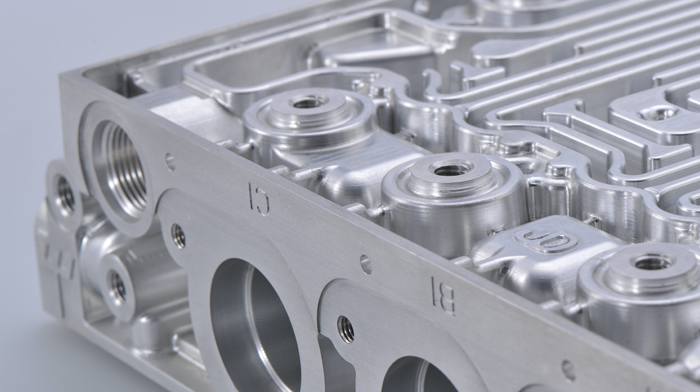

What is a mold?

A 'frame' or 'type' made of metal material to mass-produce products of the same specificationWhy should I choose Hansung Enterprise?

The most important thing in product development and production is accurate and correct design drawings, as future production processes, product completeness, and production costs depend on the design drawings.

The correct design drawings should not just be for the product, but for the properties of the product, the gates, millpins, etc. should be correctly designed to be robust and economically ejected.

Many companies do not take into account the exact conditions of the injection, which often results in a waste of your time and economic loss. However, Hansung Corporation can design, mold production, and injection in a one-stop manner, so it can be designed with various conditions in mind and can produce molds that can inject the best product.

In particular, it has a tapping and machining center from Units 5 to 16, so it is possible to manufacture molds from small to large, and it has an electric discharger that can process deep or thin parts that no longer allow tools to enter, so it is possible to process molds of complex shapes.

In addition, with the accumulated know-how and technology, various types of molds can be manufactured and repaired, including Cold Runner, Hot Runner, 2nd, 3rd, and Plate Ejecting.

- 이전

- 1/0